了解更多来自汉高粘合剂技术和汉高消费品牌 (Henkel Adhesive Technologies) 业务部旗下的技术与品牌 (Henkel Consumer Brands)。

2024年9月4日 Düsseldorf, Alsdorf / Germany

Henkel and 4JET collaborate to introduce a groundbreaking process for producing silent tires designed for electric vehicles

Lightweight construction and the absence of engine noise in electric vehicles make tire rolling noise more noticeable inside the cabin. Depending on the road surface and speed, this noise can be perceived as significantly more intrusive and unpleasant compared to combustion vehicles. Modern electric vehicles are often equipped with tires that have an acoustic polyurethane (PU) foam lining on the inside. These so-called "Silent Tires" significantly reduce noise emissions both inside the vehicle and in the surrounding environment, ensuring a considerably improved driving experience.

Silent tires for electric vehicles – a real challenge

This simple solution concept presents tire manufacturers worldwide with a complex and demanding task: a second logistics line must be integrated into tire factories to transport the lightweight but high-volume foam to the "tire wedding" at the end of the production line. This requires substantial space for logistics handling and multiple stages of intermediate storage for the foam. Numerous additional manual or semi-automatic steps are required for logistics, cutting, adding adhesives and inserting the foam into the tire. And finally, for each tire produced, the appropriate foam must be provided "just-in-sequence". As a result, the manufacturing costs of a tire increase by up to 25% and it is often impossible to integrate the technology into existing tire plants. In addition, there are significant volumes of waste generated from the off cuts of the polyurethane foam pieces.

Innovative LASER-FIT process: Direct foam in the tire with subsequent laser activation

Henkel and 4JET are now introducing a new process to produce silent tires that solves these challenges. In the innovative LASER-FIT process, a tailor-made acoustic foam is produced directly inside the tire from liquid starting materials, at the end of the tire line. This method eliminates the just-in-sequence complexity, time-consuming logistics and manual process steps, while also giving the tire manufacturer greater freedom in adapting the foam`s geometry and volume to the tire type hence also reducing waste generation.

The finished product in record time

This direct foam process, which has long been established in other industries and applications, is made possible by the patented foam activation process using a laser after the foam has been applied. Similar to a yeast dough, the foam forms an air-impermeable skin on the surface. This skin minimizes the penetration of sound into the open-pored acoustic foam and prevents sound absorption.

Dr. Rainer Schönfeld, Global Market Strategy Head in Henkel`s Automotive Component business unit, explains: ”Our new to market Loctite LASER-FIT acoustic foam achieves its sound absorption effect through a large inner surface and a pore design specifically tailored for tire noise suppression. Without 4JET`s laser activation process, which precisely removes the foam skin, the majority of sound waves would be reflected off the foam surface instead of being absorbed. This great idea is a prime example of the innovative strength of German SMEs, which continue to be the engine of our economy!”

George Kazantzis, Global Head of Henkel`s Automotive Components business unit, adds: “This revolutionary direct-foam-to-tire technology represents our joint commitment to innovation and sustainability. By eliminating the transportation of pre-fabricated foam and reducing cutting waste, we will enable our customers to lower their carbon footprint.”

Following the presentation of the process concept at TireTech in Hanover this March, the partners succeeded in developing the process in record time. Dr. Armin Kraus, co-CEO of the 4JET Group, stated: “In Henkel, we have found the ideal development partner for this innovation. Henkel combines expertise in the development of technically sophisticated PU foams with their mechanical application like few companies in the world. At the same time, Henkel has the necessary industry knowledge in the automotive industry as well as the global footprint required to reliably supply the tire industry worldwide with products of consistently high quality. We witnessed this. What impressed us most was the passion and speed with which Henkel works. From the idea to the finished application in record time: we will be presenting our joint complete solution at RubberTech24 in Shanghai this month.”

About 4JET

The Alsdorf-based 4JET Group provides solutions for the surface technology of the future. The company was founded in 2006 and supplies tire manufacturers, among others, with solutions for tire marking, mold cleaning and adhesive preparation. Its customers also include major OEMs and other automotive suppliers. The 4JET microtech business unit supplies laser micromachining systems for processing technical glass, solar cells and other high-tech components. The company employs around 200 people, including around 80 engineers and scientists. Subsidiaries in Shanghai and Atlanta offer international customers sales advice and technical services.

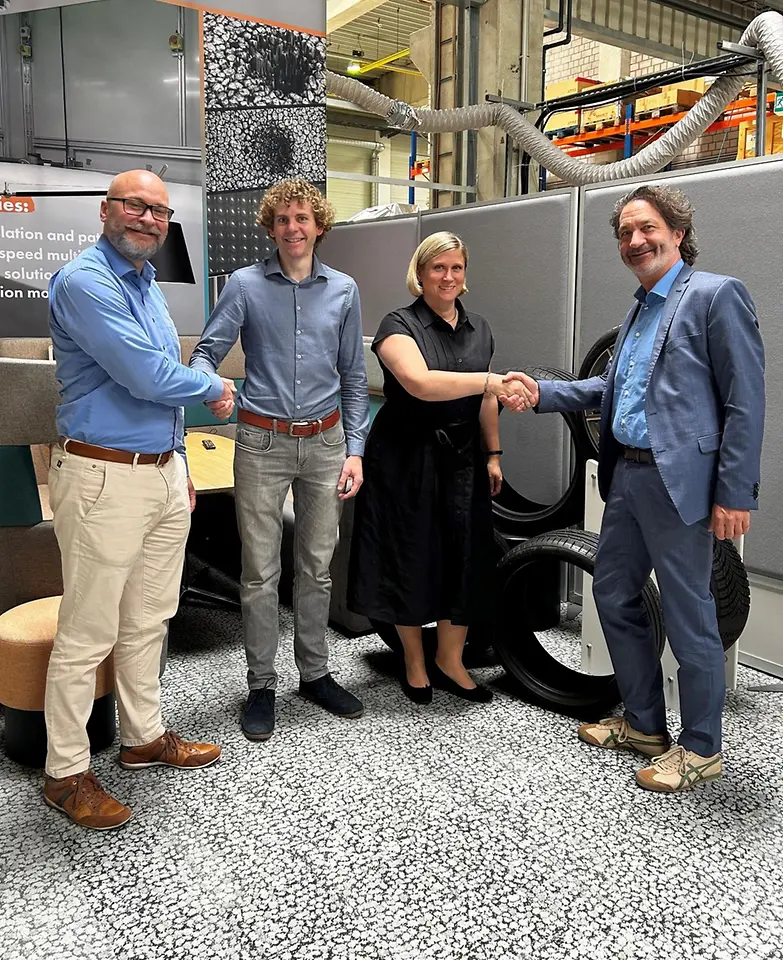

Collaboration between Henkel and 4JET: Dr. Armin Kraus, co-CEO at 4JET, Imke Vogel, Market Segment Head Automotive Components Europe at Henkel, Dr. Jan Flohre, Head of Laser Process Development at 4JET and Dr. Rainer Schönfeld, Global Market Strategy Head Automotive Components at Henkel (from right to left).